Nitinol Machining for Precision Applications

Some metal alloys are known to exhibit superelasticity and shape memory behaviors. These unique material properties of shape-memory alloys (SMA) are due to their ability to undergo phase transformations between martensite and austenite when subjected to temperature changes and/or external loadings and recover upon reversal of such. Nitinol, comprised of nearly equal parts Nickel and Titanium, is an SMA with excellent biocompatibility, in large part due to its good corrosion resistance. Its unique properties make it an ideal candidate for modern-day implantable medical devices such as neurovascular stents, heart valve frames, and orthodontic archwires.

These advancements in medical device technologies have been made possible not only by the use of Nitinol material but also because of advancements in state-of-the-art laser technologies for manufacturing these devices. In particular, the use of ultrashort pulse laser technology is beneficial since the shape memory effect is sensitive to material heating during device manufacturing (i.e. cutting). Many early Nitinol-based medical implants manufactured using longer pulse width lasers experienced in-vivo fractures, likely due to material fatigue and subsequent cracking. Nitinol’s sensitivity to excess heating during device manufacturing makes femtosecond laser technology an ideal choice for processing it, especially given the demanding quality requirements of advanced medical device manufacturing.

Figure 1. 0.2 mm thick Nitinol cut with different PRFs, with set average power

of 8 W and 2 mm/s cutting speed.

When cutting Nitinol for medical device manufacturing, low kerf width, high aspect ratio, low heat effect to surrounding material and high throughput are important requirements. To understand the limits of laser processing parameters to achieve the above requirements, a study was conducted at the MKS Spectra-Physics® industrial applications laboratory. Using a Spirit HE 1040-16 industrial femtosecond laser system, 0.2 mm and 0.5 mm thick Nitinol sheets were cut with varying pulse energies, pulse repetition frequencies (PRF), pulse durations and assist gasses. It has been found that the quality of the cut depends on the pulse energy, PRF and thickness, with thicker sheets requiring more pulse energy and therefore lower pulse repetition frequency (PRF). For 0.2 mm thick material, machining at 200 kHz with 40 μJ was optimal whereas 0.5 mm thick material required the higher pulse energy (80 μJ) available at 100 kHz.

Figure 2. 0.5 mm thick Nitinol cut at different speeds with helium as assist

gas and PRF=100 KHz, pulse energy = 80 μJ.

The throughput as defined by cutting speed was found to also depend on the assist gas. Helium gas was found to be the best overall assist gas compared to air, nitrogen and argon. With helium, 0.5 mm thick Nitinol sheet was cut at 0.8 mm/s with no blackening or heat effects at the edges of the cut. With argon, while cutting speeds were higher at up to 1 mm/s, the back surface quality showed blackening at the cut edges. When using air and nitrogen, max cutting speeds were found to be significantly lower, at only 0.3 mm/s and 0.4 mm/s, respectively.

The difference in cutting speed/quality with different assist gases may be due to a difference in plasma dynamics at the beam focus. As the breakdown threshold for different gases is different, the intensity of breakdown occurring at the focus was also found to be different for the different gases.

Figure 3 shows the breakdown at the focus with nitrogen and helium as assist gasses.

Figure 3. Air-breakdown with different assist gasses.

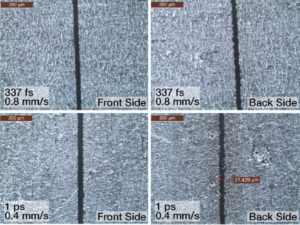

When cutting with longer pulse durations, both throughput and quality deteriorated. Highest speed and best quality were achieved with the shortest pulse widths. At 337 fs, a cutting speed of 0.8 mm/s was achieved in 0.5 mm thick Nitinol using helium assist gas. The quality on the front and back surfaces of the samples show no blackening or heat-affected zone (HAZ). On the other hand, with 1 ps pulses the maximum cutting speed was only 0.4 mm/s and cut edges were blackened on the back side. The same trend was observed when other assist gasses were used.

Figure 4. 0.5 mm thick Nitinol cut with 337 fs pulses and 1 ps pulses, with helium

as assist gas and PRF=100 KHz, pulse energy = 80 μJ.

Nitinol cutting for medical device manufacturing often has demanding requirements on quality and throughput. Processing the material without altering its unique inherent natural properties is challenging for longer pulse width lasers. Hence, femtosecond lasers are ideally suited for processing advanced medical devices that incorporate it. With its short pulse widths and high pulse energies, the Spectra-Physics Spirit HE 1040-16 industrial femtosecond laser offers optimal laser parameters for processing a range of Nitinol thicknesses with excellent throughput and quality.

Per maggiori informazioni sui prodotti correlati vai alla nostra pagina: