Prismatic and Pouch Battery Cell Welding

Introduction

As the popularity of Prismatic and Pouch Cell batteries continues to grow, so too does the demand for larger cell capacities and increased energy density. A need for new, innovative joining methods is emerging. Specifically, the ‘foil-to-tab’ weld that is used to connect cells (consisting of 6-20μm Copper or Aluminum foils in ever increasing stackable quantities) to battery terminals (Ni coated Cu or Al Tabs) is challenging the limitations of currently utilized technologies.

Current Process

Typical processes for welding Anode and Cathode Interconnects involve either a two-step process, including ultrasonic and laser welding, or a process consisting of a single ultrasonic weld. In the past, IR lasers have been employed to take on this task, however they have many drawbacks including absorption inefficiency, the ablation effect, and the tendency to spatter. With ultrasonic welding the foil stack quantity is limited as this contact process becomes ineffective in joining the entire stack.

Testing

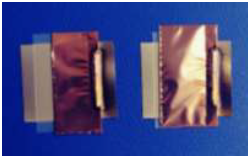

The AO-650, in combination with the BlueWeld 100 focusing head, (Figure 2) has been used to demonstrate the capability of using a blue laser for this process. Figure 3 shows a weld of ~40 layers of 10μm Cu foil completed in a single step. The use of edge welding, as opposed to lap welding, allows for the reduction of the amount of power required and provides a larger process window in general. Figure 4. demonstrates the weld quality, lack of gaps in adjacent foil and lack of porosity within the weld structure. The welded samples demonstrate superior pull strength and acceptable cross-sectional area for demanding applications. This process helps to mitigate excess heating of the part as the blue laser is more efficiently absorbed into the material. Welds have also been conducted on a range of Aluminum foil stack thicknesses with promising results.

Summary

NUBURU’s line of blue lasers eliminates the need for a two-step process and provides the capability for ever increasing foil stack thicknesses. Wider process windows, along with better weld characteristics, give blue a clear advantage over current technologies.

Figure 1. Prismatic cell example

Figure 2. AO-650, BlueWeld 100

Figure 3. Cu foil weldedn on Ni-coated Cu tab

Figure 4. Cross section of Cu foil weld

Per maggiori informazioni sui prodotti correlati vai alla nostra pagina: